Finally the

procedure we have all been waiting for the "A4 Timing Belt

Procedure" including the Automatic and Manual transmission

differences. Some people have argued till they are blue in the

face that "mark and pray" was the easiest way to change one of

these belt, and it has been proven that this belt can be

changed in under 2 hours using the full factory method as

demonstrated here in this thread. The procedure utilizes all

the factory tools and processes. The reason for going to the

extreme of utilizing all the tools is the elimination of all

possibilities of making a $2500.00 mistake and destroying the

head.

You do not need many tools to complete this job. What you

do need is a thorough understanding of the procedure and what

you are about to accomplish. When changing a timing belt you

are doing more than just replacing an old belt. What you are

doing whether performing a 40K on the auto or 60K on a manual

is inspecting the entire engine area that has been covered up

since the engine was new or since the last belt change.

The second most important thing this procedure accomplishes

is it totally resets ALL timing setting on the engine and

restores them back to Factory new settings. While on the topic

of timing we need to understand that there are three types of

timing involved here. The first and most overlooked type of

timing is the cam and crank timing. This keeps the cam

spinning in perfect time allowing the engine to produce great

low end power as well as allowing the engine to rev to it's

full redline of 5100 rpm.

The second type of timing is "Basic" injection timing. I

concocted the word "Basic" timing because it is used to

initially set and assure that the engine will start. This is

accomplished by inserting the injection pump lock pin

positioning the pump shaft in relation to cam and crank timing

in such a way that injection will occur within the ignition

window.

Once the cam & crank timing have been set and the

Injection pump is positioned you will need to adjust the

injection timing utilizing the Vag-Com http://www.ross-tech.com/

If you do not have this then get it before attempting to

perform this procedure.

This leads me to my next point, tools. Everybody wants

to know where to get them and how much they cost. The simple

fact is they are not cheap, but neither is your engine... I

use the factory tools that I got from http://www.zelenda.com/ .

They sell all the tools you need for the job and they are the

same tools the factory used to assemble your beloved engine so

again it's your engine and your money.

The VW Factory tools you are going to need are:

-3036

Camshaft holding bar

-3418 Camshaft setting bar

-2587 2

pin spanner wrench (don't use a bicycle wrench this one costs

the same!)

-3359 Injection pump lock pin

-T40001 puller

set

Specialty tools your going to need from Sears:

-41831f

Serpentine belt tensioner tool

-44360 11mm&10mm 45

degree offset wrench

-5mm 3/8 drive allen socket

-6mm

3/8 drive allen socket

-T25 Torx bit(1/4" drive)

Specialty tools from AutoZone:

Flat Band clamp tool

Other tools and "stuff"

(1) Block of wood, a 2x4 6" long

will work great

(2) Jack stands (strong enough to support

your car!)

(1) Hydraulic floor jack

Tools you have to make:

stubby 5mm 1/4" drive socket

Not to mention a set of metric 1/4, 3/8 and 1/2" drive

sockets and extensions.

Now the fun part! I have to add If I have to explain

how to remove the belly pan and the engine cover you may want

reconsider performing this job and take it too your local

dealer...no joke.

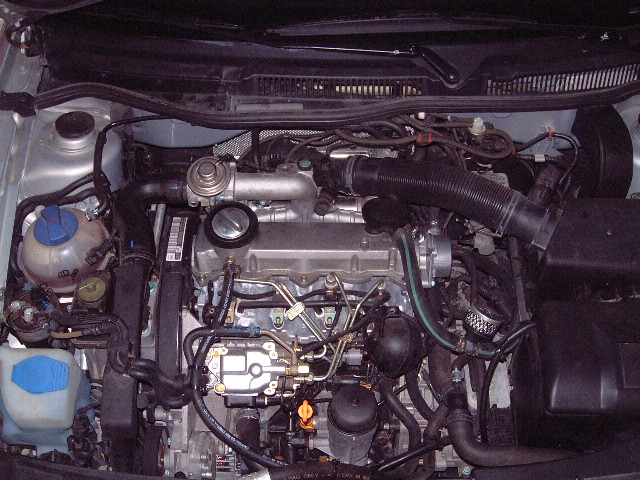

This engine represents a majority of the forum members

in that it has an oil bypass filtration system, bypassed CCV

system (Thank God no oil to drip on me !) and he is a proud

member of Epsilon!

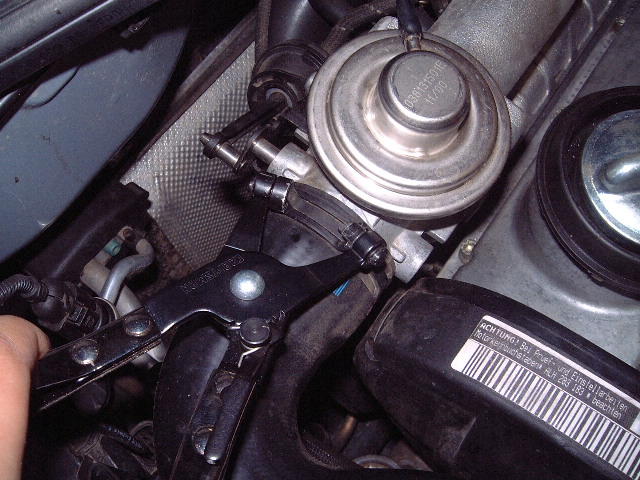

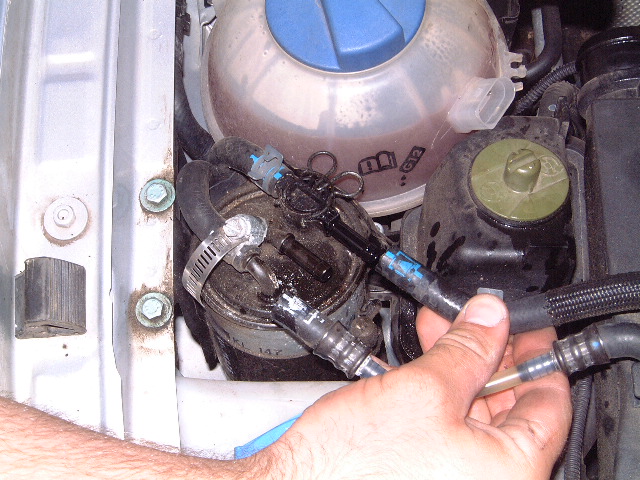

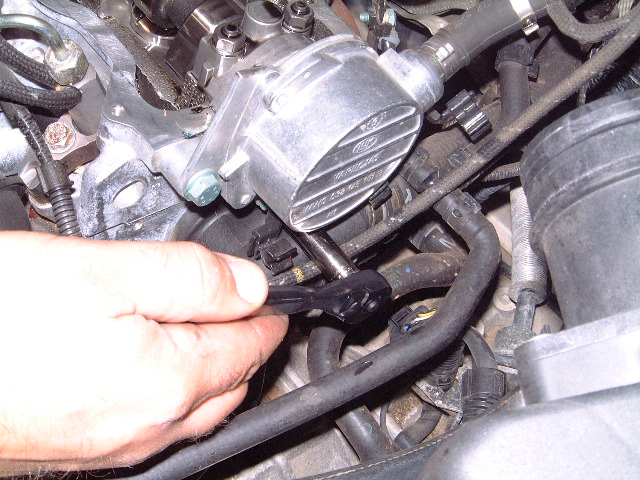

Using the "Flat Band Clamps" remove the intake tube

going into the EGR/intake manifold

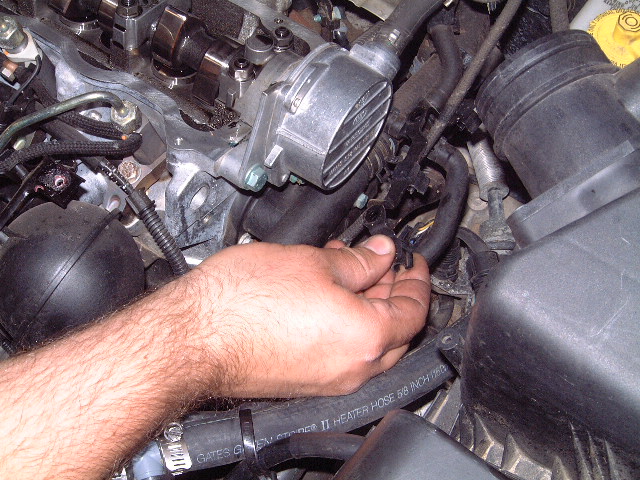

Remove the coolant reservoir connector, hose clamp and

two philps screws.

using a 5mm 3/8 drive allen socket and extension,

remove the allen bolt securing the power steering reservoir to

the engine mount

Remove the two fuel lines coming off of the fuel

filter, cap them off and insert them through the oil dip

stick

Stuff some paper towels into the intake to prevent

"Murphy's Law" from kicking in and prevent you from dropping

that flying spring clamp into an intake duct!!

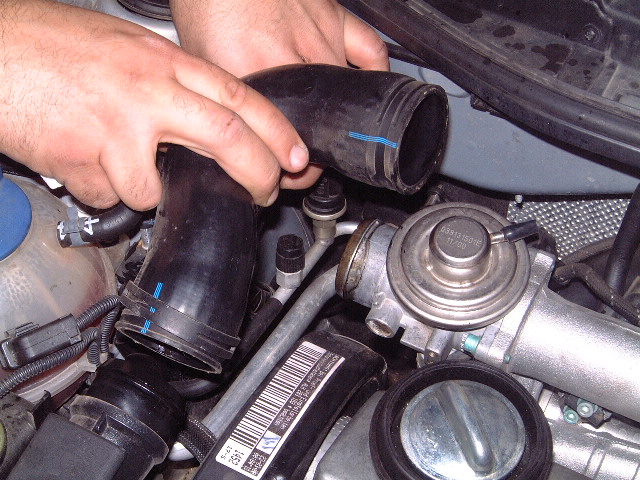

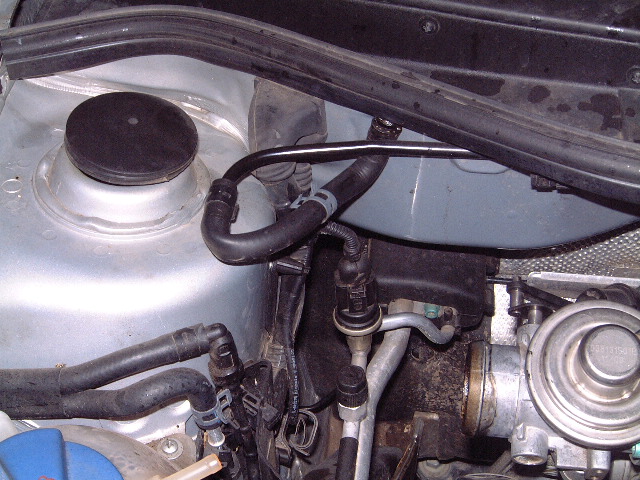

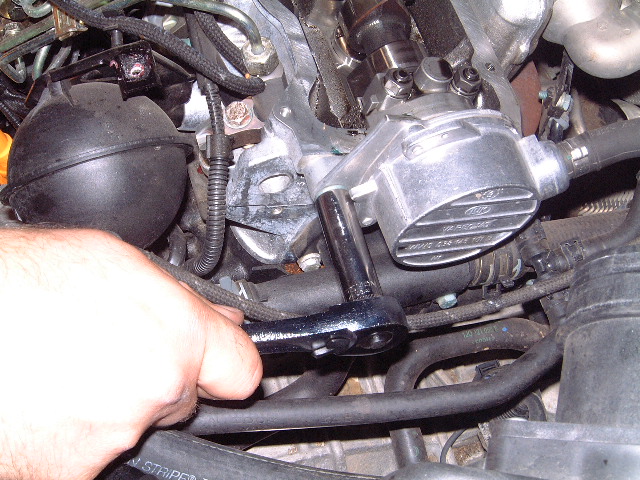

Raise up the power steering reservoir and pull the

coolant reservoir hose under and to the front of the car. let

the coolant reservoir hang on the front of the car.

Remove the timing belt cover, and the flex line coming

from the air filter going to the engine, I strongly suggest

stuffing some paper towel in both holes to prevent you from

dropping something into the turbo inlet.

Using a 5mm 3/8 drive allen socket, remove all the

front and driver side rear allen bolts except for the two by

the oil filler cap. For those use the special cut-off 1/4"

drive socket that you made to remove them. Believe me when I

say this, I have tried EVERY possible way to do this and I

have stripped out a few heads in the process and this by far

is the only true easy way to do it.

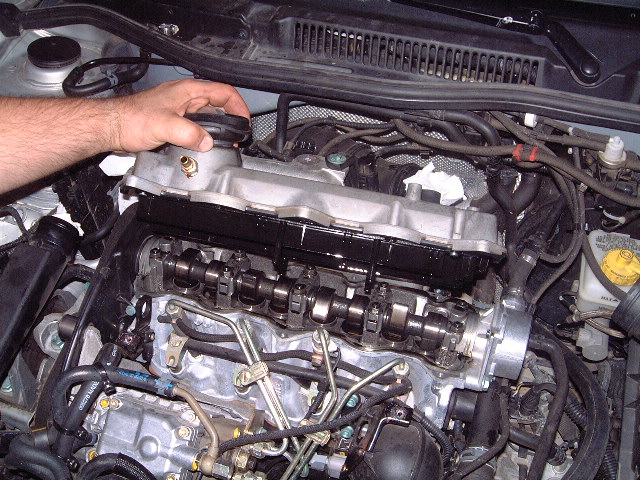

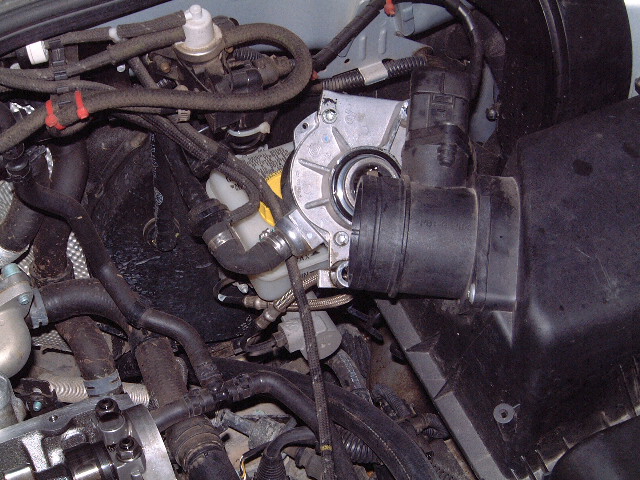

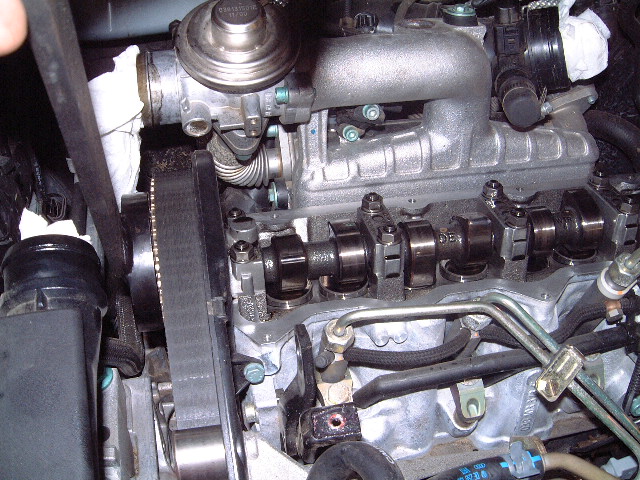

Lets look at the head and gauge what we are going to

do. On the right side of the camshaft is the vacuum pump,

there is a slight difference in removal procedure between the

auto and manual (not a big deal by the way). Anyway on the

left side of the cam look at the first two lobes. These two

lobes MUST ALWAYS be returned to the "both up" position, why

you ask? If you don't its not a matter of if but you WILL wet

the cam timing 180 degrees out of time don't ask how I can

only say from my experience and that of others that it can and

does happen. By the way this is a great example of a SUPER

clean engine using Delvac 1 5w40 full synthetic, the best oil

out there that meets the VW TSB oil viscosity

specifications....had to through that in there

Remove the vacuum line running under the vacuum pump.

MANUAL TRANSMISSION OWNERS, REMOVE THE CENTER GLOW PLUG

WIRE AT THIS POINT AS WELL

Using a 1/4" drive deep socket remove the lower 10mm

nut. MANUAL TRANSMISSION OWNERS, USE THE 45 DEGREE OFFSET

10MM WRENCH AND REMOVE THIS NUT. THE NUT WILL BE BETWEEN THE

COOLANT HEATER HOUSING AND THE VACUME PUMP AND THIS WRENCH IS

THE ONLY WAY TO GET IT OUT WITHOUT REMOVING THE COOLANT HEATER

HOUSING.

Using the 10mm deep, remove the aft 10mm nut, this is

the same for the manual owners as well, then remove the vacuum

line support bracket.

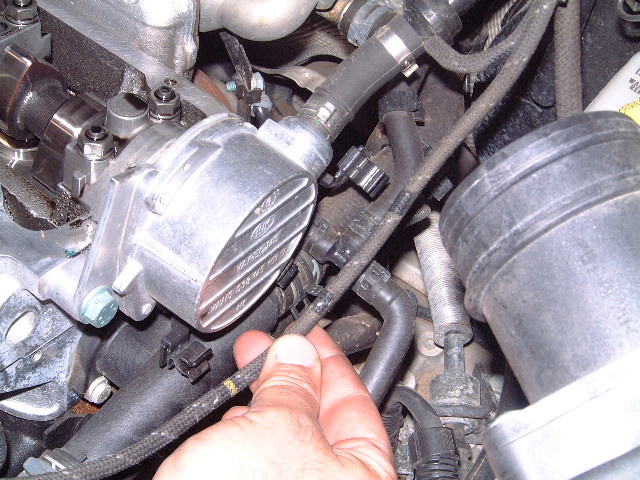

Using a 13mm deep socket, remove the front vacuum pump

bolt There are three of these 1 normal bolt and the other two

have a threaded bolt on the top for the vacuum line support

bracket

Remove the rear vacuum pump bolt

Remove the lower 13mm bolt. MANUAL TRANSMISSION

OWNERS, USE A 13MM BOX WRENCH TO GET IN AND REMOVE THIS BOLT.

THE COOLANT HEATER HOUSING WILL PREVENT YOU FROM USING THE

DEEP SOCKET (BUT I SUPPOSE YOU HAVE NOTICED THAT...)

Remove the vacuum pump and bend it out of the way, you

won't damage the line by bending it just make sure it does not

fall damage could result.

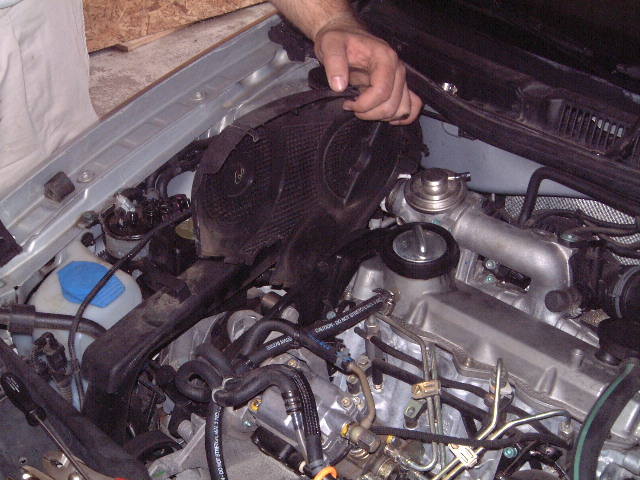

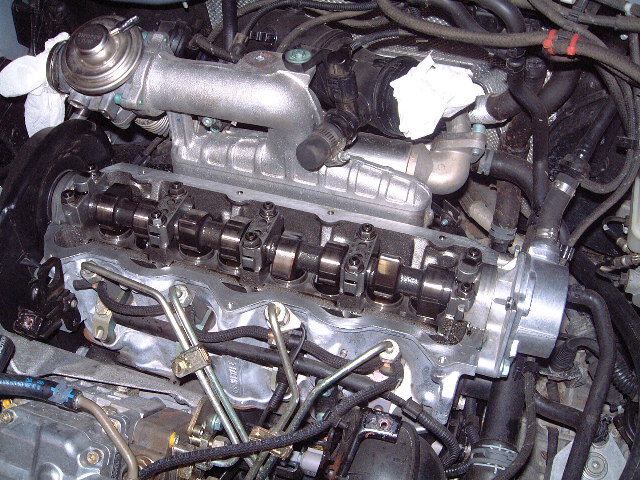

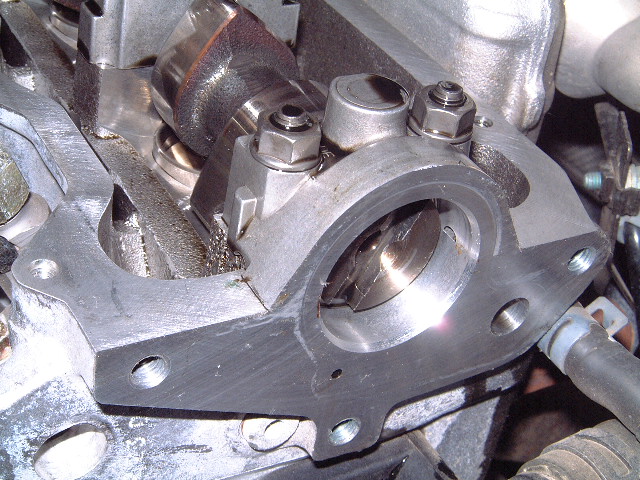

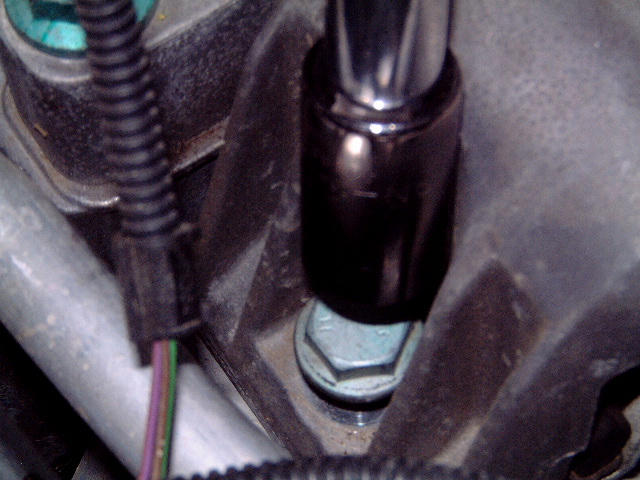

Here is a picture of the end of the camshaft. The

groove in the end of the cam is where the 3418 Cam setting bar

is inserted. In a later step the groove as you would suspect

will need to be rotated, the 3036 Cam Holding bar will be used

to turn the engine into the correct position.

Using your two jack stands and a hydraulic jack, lift

the car and support it at a height that is comfortable for you

to get under the car. Now crawl under and remove the engines

belly pan

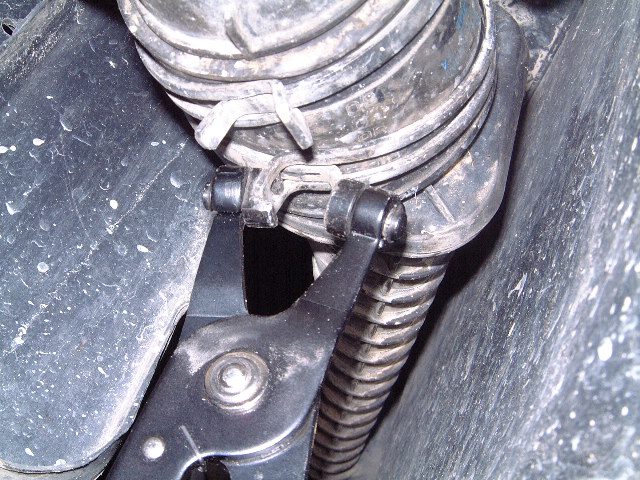

Crawl under the car and at the back of the engine above

the passenger side drive shaft is the turbo compressor outlet

pipe. Using your "Flat Band Clamps" remove the spring on

turbos Compressor outlet and pull the hose off of the outlet.

Use a 10mm socket and remove the nut on the turbo to

intercooler pipe, then use the clamps and remove the clamp on

the intercooler and remove the whole duct assembly.

[b]Remove the washer nuts using a long screwdriver by

un-screwing them, or you can just pull off with some force but

you may damage the washer so try this as a last resort. Then

remove the side lower panel.

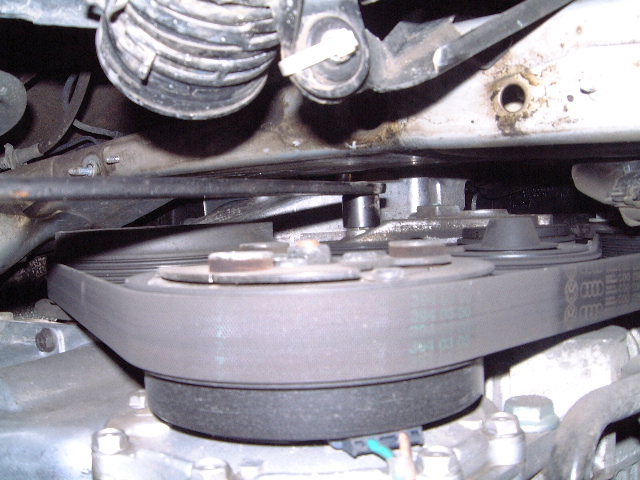

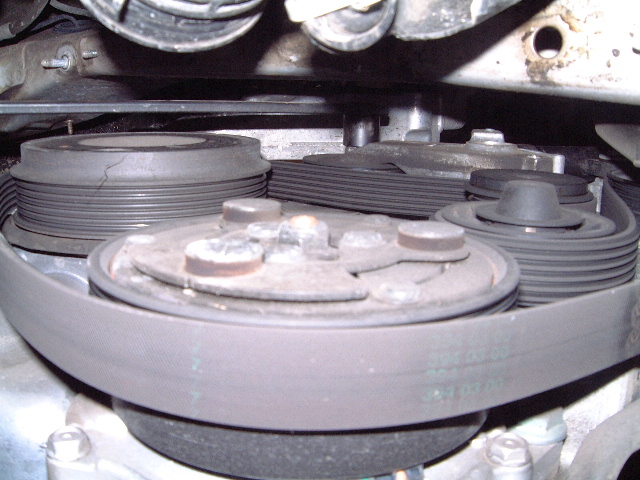

Using the Craftsmen 41831f Serpentine belt tensioner

tool and the special short 16mm socket that came with the

tool. (FYI a standard socket WILL NOT fit in this small space)

Relieve the tension on the serpentine belt tensioner and

remove the belt.

Using the 3036 Cam holding bar, rotate the engine until

the cam lobes on the #1 cylinder (passenger side in "Normal

world") are in the "Lobes up position and the groove in the

cam pulley is level with the machine finished valve cover

deck.

Install the 3418 Cam setting tool into the groove, you

may need to work the cam back and forth a bit with the 3036

tool. The 3418 has a nit of flex to it so it hold the bar nice

and tight in the groove preventing the cam from moving. In the

A3's you needed to use feeler gauges but in the design of this

tool they built in tension that eliminates the need to use

feeler gauges as depicted in the Bentley Manual. THIS IS A

GOT-YA, MAKE SURE THE #1 LOBES ARE IN THE LOBES UP POSITION

BECAUSE OF THE FLEX IN THE 3418 TOOL IT IS POSSIBLE TO FORCE

IT INTO THE GROOVE ON THE CAMSHAFT EVEN THOUGH ITS 180 DEGREES

OUT, TRUST ME ON THIS ONE hehehe

NOTE TO AUTOMATIC OWNERSThis is where the

Bentley fails at depicting what you are looking for. On the

flywheel you are looking for a stamped circle with a "minus"

sign on either side. The first link shows the timing mark when

the cam setting bar was first installed. It should look like

the second link with the circle and dashes at the very bottom

of the window. At this point do not worry about the crank

timing it is however "VERY" important for you to know what it

looks like because of all the marks that can be construed as a

"TDC" mark.

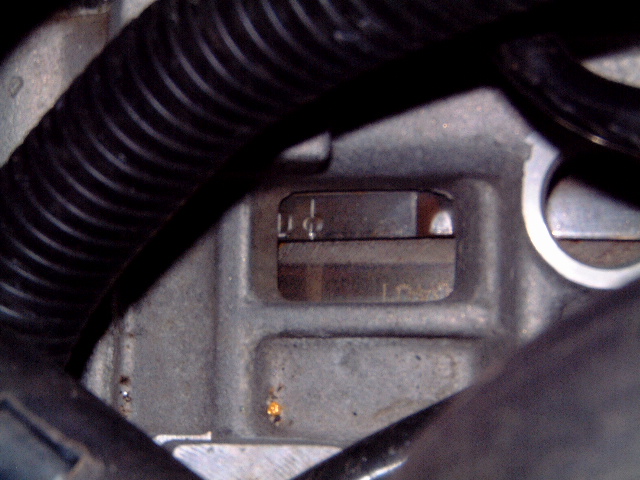

NOTE FOR MANUAL TRANSMISSION OWNERS this is a

picture of the timing mark and the hole to observe it through.

The hole is located at the very top of the transmission

bellhousing (12 O'clock postion).

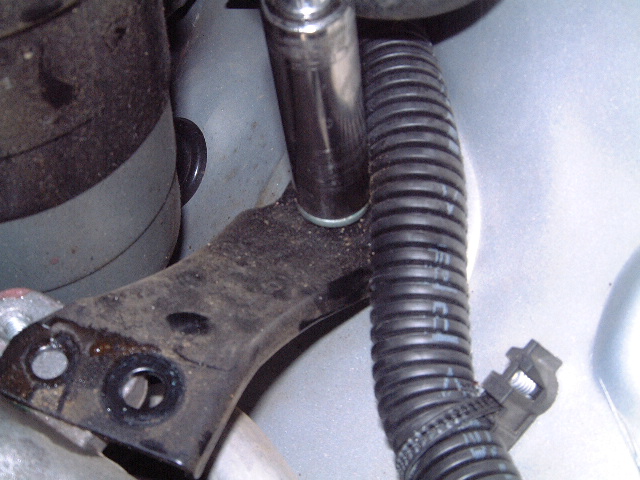

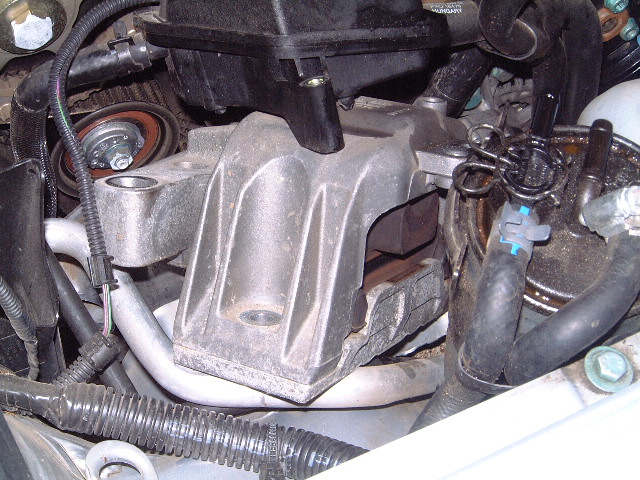

Moving back over to the Pendulum Engine mount by the

Power steering reservoir, use a 13mm with an extension to

remove the steel engine mount alignment plate.

Remove the two lower bolts using a 1/2" drive and 16mm

socket If you have to use an 18mm these are the WRONG

BOLTS!

Grab your hydraulic floor jack and the 6" 2x4 piece of

wood, position the wood and the jack on the rear passenger

side corner of the oil pan. NOTE: MAKE SURE THE WOOD IS ON

THE EDGE THE REASON IS STRUCTURALLY THIS IS THE ABSOLUTE

STRONGEST PART OF THE PAN AND WILL PREVENT YOU FROM CRUSHING

IT IF ANYTHING WERE TO SHIFT OR DROP. Once the jack is

positioned under the pan lift the engine until the engine

weight is off of the mount and so that the engine mount is off

the car frame by about an inch.

With the engines weight off of the engine mount use a

1/2" 18mm socket and breaker bar (this is a tight bugger) and

remove both of the remaining engine mount bolts.

Slide the engine mount out of its position and remove

from he car.

Now carefully raise the engine on the jack until the

engine mount bracket hole is exposed so you can get a socket

in. Don't worry you will not damage the other mounts in doing

this. You may have to raise the engine quite a bit so don't be

surprised (your knuckles will thank you the higher you raise

it...) Now use a 3/8 drive ratchet and a deep 16mm socket and

remove the front and center engine mount bolt and the super

secret hidden rear one, this one you will have to find by

feel, but I can assure it is there!

Lower the engine on the jack so that you can have

access to all four of the allen bolts on the Harmonic Damper.

Then use a 3/8 drive ratchet or breaker bar and a 3/8 drive

6mm allen socket break loose and remove the allen bolts.

NOTE: DO NOT USE AN EXTENSION OR ELSE YOU RISK STRIPPING

THE BOLT HEADS. FYI the cam setting bar will kee the

engine from moving. On the manual you could put the engine in

gear and keep it from moving by having somebody hold the brake

pedal down, so this method works for both but at least the

manual tranny folks know there is an option.

Use a 3/8 drive ratchet and 16mm socket to break loose

the engine mount but don't remove the bolt yet.

Get a 1/4 drive and a 10mm deep socket and remove the

(5) bolts that hold the timing belt cover plates on. Remove

the last 16mm bolt holding on the engine mount and push the

mount upward to remove the top timing belt cover plate

NOTE: THE TOP COVER CAN ONLY BE REMOVED ONCE THE LOWER

ENGINE MOUNT BOLT IS REMOVED. WHEN RE ASSEMBLING THE ENGINE

THE LOWER COVER MUST BE INSTALLED FIRST FOLLOWED BY THE TOP

COVER THEN THE ENGINE MOUNT CAN BE INSTALLED IN THAT

ORDER. Also notice the rotational direction of the timing

belt. Look for oil leaks or anything that is out of order, now

is when you want to find it.

Remove the 13mm nut on the tensioner, and using the

2587 Two pin spanner wrench and relieve the tension on the

timing belt tensioner by rotating the wrench

counter-clockwise.

Using the 3036 cam holding bar and a 19mm 1/2" drive

socket loosen but DO NOT REMOVE THE BOLT ON THE CAMSHAFT. The

bolt at the factory was tightened to only 33 ft-lbs. so it

should not require much force at all to loosen this bolt.

NOTE: I HAVE RUN ACCROSS A FEW BOLTS THAT WERE WAY OVER

TIGHTENTED, USE EXTREME CARE IN REMOVING THESE TYPE OF

BOLTS!!!! IF THIS IS THE CASE I STRONGLY SUGGEST REMOVING THE

CAM SETTING BAR UNTIL THE BOLT HAS BEEN LOOSENED AND THEN

REINSTALLING IT.

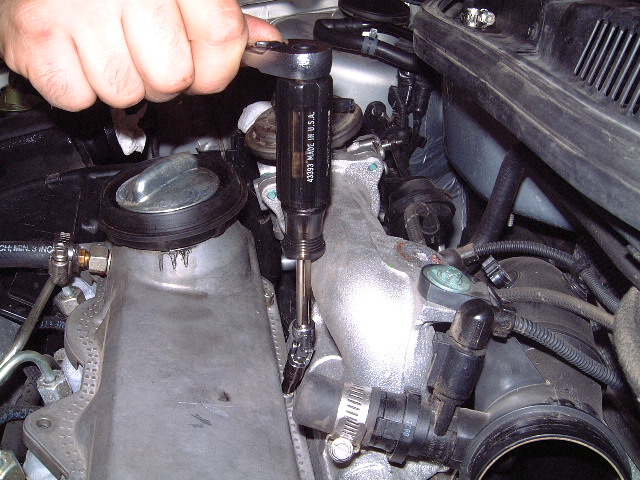

Install the T40001 puller using the 2 prong puller and

one of the single prong pullers (it comes with 2 single prongs

and one 2 prong grippers). Install the puller making sure that

there is a gap between the washer and the pulley. Use a 17mm

box end wrench and turn the puller until the pulley "SNAPS"

(it will scare you if you don't expect it) off the tapered end

of the camshaft.

Remove the cam pulley bolt, the pulley and the

tensioner pulley from its shaft

Holding the engine mount away from the engine slide the

old belt between the mount and the block, if you have not

noticed yet the mount cannot be removed unless the engine is

removed from the car... Remove the belt and inspect it for any

cracking or rubbing damage. This is when you want to make sure

the belt was wearing normally with only minor cracking or wear

marks visible. If any abnormal wear marks are present you need

to determine how and where they came from so that you do not

install a good belt in a poorly aligned engine pulley

system.

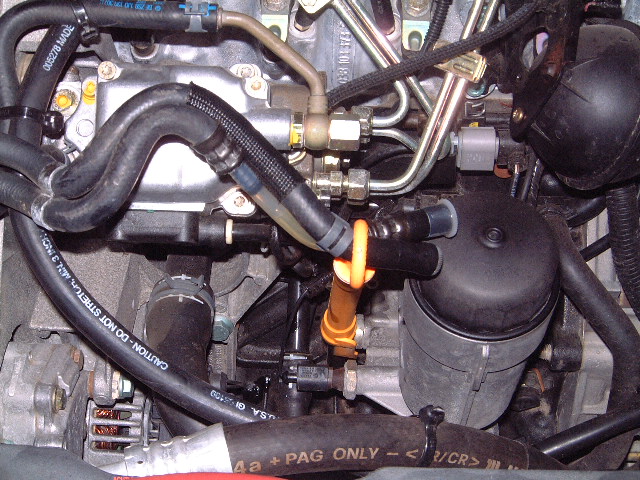

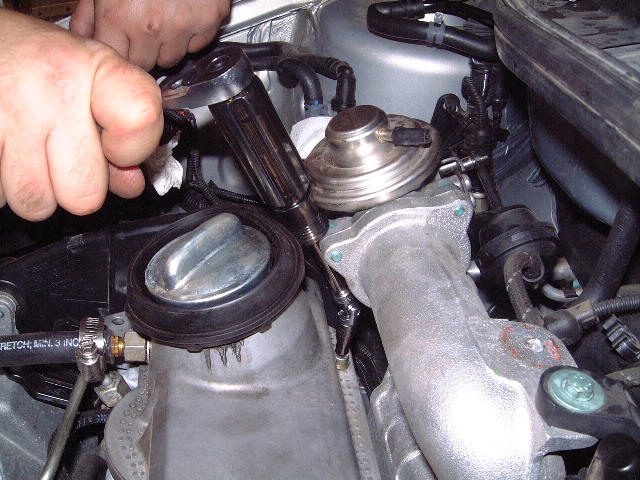

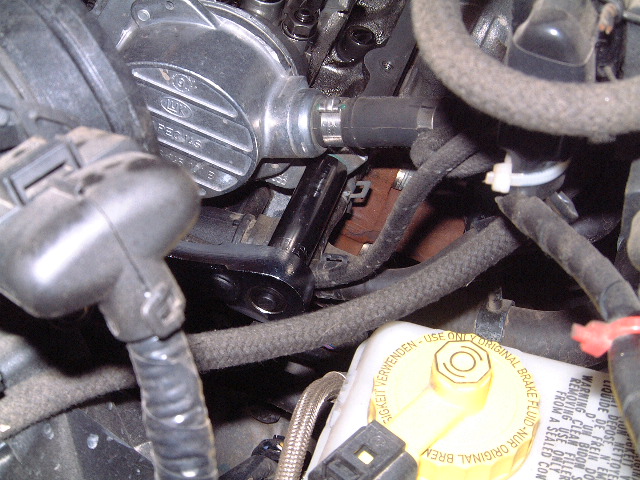

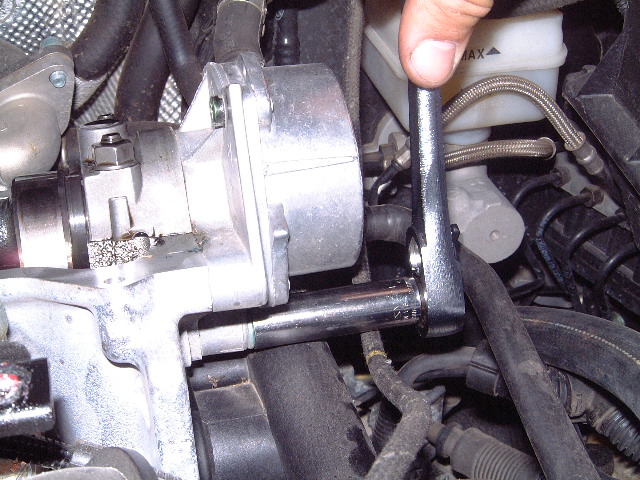

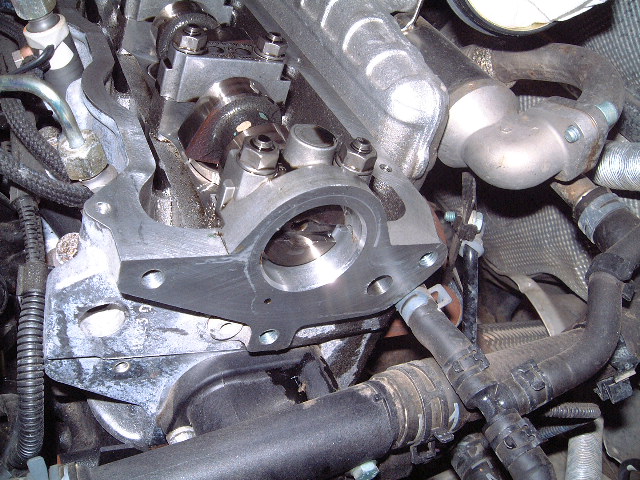

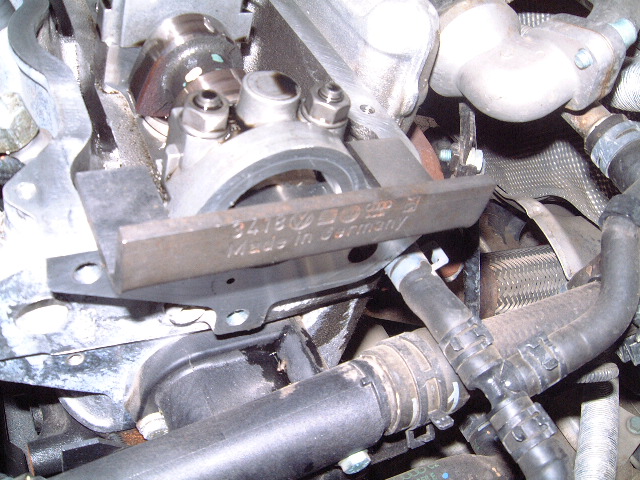

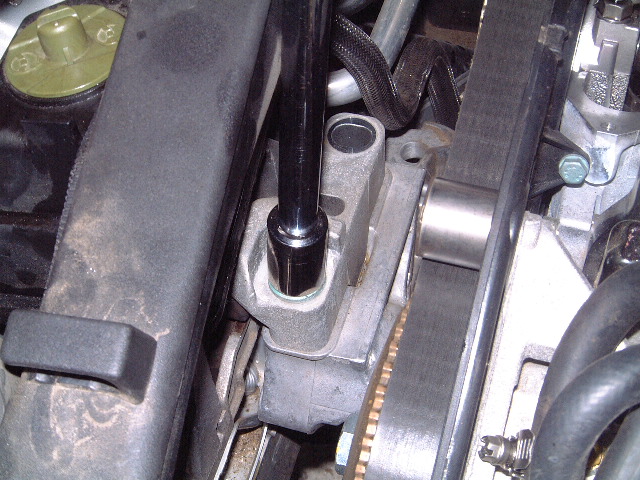

The first picture is a shot of the hole the 3359

Injection pump lock in gets installed into. The second

pictures shows me using a crescent wrench to turn the center

bolt to align the pin hole so that I can insert the lock pin.

The last picture shows the orientation of the pin relative to

the center of the pump. NOTE: IT IS POSSIBLE TO INSTALL THE

PIN TO THE RIGHT OF THE HOLE AND HAVE THE INJECTION TIMING OFF

BY ABOUT 30 DEGREES, WHICH HAPPENS TO BE OUTSIDE THE IGNITION

WINDOW, A NO START WILL RESULT. FYI DO NOT try and turn

the whole motor over using the injection pump center bolt! Use

the 3036 tool. Rotating only the pump such as I have

demonstrated will not loosen or throw the pump shaft alignment

off since I am only turning the pumps pulley with out a timing

belt installed.

NOTE THIS IS THE AUTOMATIC TRANSMISSION TDC TIMING

MARK. If you look at the first picture notice that the

circle is at the base of the window, this is what you want. If

you have to turn the crank use a screwdriver and gently push

the fly wheel in the direction you need to go to get the TDC

in the correct position of the window. Then insert the small

screw driver to prevent the flywheel from spinning when

installing the new belt.

NOTE: THIS IS THE TIMING MARK ON THE MANUAL

TRANSMISSIONS. Make sure the mark lines up with the

aluminum tooth at the top of the hole.

This is a picture of the water pump. If you have

120,000 miles or more consider replacing it. It's only a few

bolts and a gallon or so of coolant. This is a great time to

do the job if you have high mileage.

Here is a picture of the timing belt and its part

number for the A4 TDI. I strongly suggest making it very clear

to the part supplier what type of car you have. It has

happened more than once a part counter guy has looked up and

sold the wrong part leaving you with a car that is out of

commission and the possibility of facing a backorder!. Take

your time when researching the parts and double check you have

the correct parts before beginning this job, at this stage in

the game is the last time to realize the belt or tensioner DO

NOT fit!

Hold the belt up and install it so that the curves go

this way, it makes it easier to install the belt around the

pulleys.

[b]Holding the engine mount away from the engine slide the

new belt back under and onto the engine. Route the belt around

the appropriate pulleys, in case you forgot how they go on the

lower pulleys here is a snap shot for you:

[b]Install the new tensioner. In this picture you see the

two holes on the inner hub at the top of the shaft, you DO NOT

want it here. rotate the two holes so that they are at the

bottom. Also make sure that the alignment prong is engaged in

the slot in the head. Go ahead and install the nut finger

tight only.

Starting from the crankshaft and working counter

clockwise of the belts path around the pulleys take out the

slack and make sure the belt is engaged in all the pulley

teeth on all the pulleys. Once you work your way back up to

the camshaft install the cam pulley into the belt and slide

the pulley onto the cam. This may take a couple of tries but

it will go on, the belt is going to be very snug. What you are

working against is injection pump pulley. Once you get the cam

pulley on install the cam bolt but DO NOT TIGHTEN, make sure

it is only finger tight!.

Once the cam pulley is on, loosen but do not remove the

three blue bolts on the injection pump. This will relieve the

stress on the belt betwwen the injection pump and the camp

pulley as well as the lock pin. I suggest getting the new

style non-stretch bolts, the older style stretch type were

depicted by an "x" in the part number Avoid these if possible.

The new style non-stretch are suitable for use on ALL A4

TDI's.

You can visually determine the non stretch style bolt by

looking to see if the bolts have threads all the way up the

shaft to the integrated washer head, the stretch type threads

stop half-way up the shaft. Anyway when you loosen the

injection pump bolts remove one to inspect it for the type of

bolt installed.

With the 3 pump bolts loosened and the injection pump lock

pin installed this will assure you that the injection pump is

set within the ignition window. I call the setting "basic"

pump timing as it pertains to a mechanical setting rather than

anything to do with the ECU or "Basic Settings" as recognized

by the VAG-COM. Keep in mind having the pump set with the pin

will only assure you the engine will start and run, however it

will not give you an optimum setting for efficiency or power.

At the end of the procedure I will explain how to adjust the

timing using the VAG-COM to get the best power and economy

from your TDI.

Snug up the 13mm nut just enough and insert the 2587

Two Pin spanner and rotate the tensioner "CLOCKWISE" until the

marks (a tooth and a groove) are lined up as depicted in the

last picture. You will notice that when you set the tension

the cam pulley and the injection pump pulley will move as you

take up the slack, this is the whole idea of doing it this

way. The magic is even though the pulleys move the pump, cam

and crank all remain in perfect time! Now lock down the bolt

"Good'n Tight" is a good torque setting.

Double check that the engine mark is still at TDC, the

injection pump lock pin is inserted all the way into the pump,

and that the Cam locking bar is fully seated. Now using the

3036 Cam holding bar torque the bolt to 33ft-lbs. I usually

add just a hair but under no circumstance should this bolt be

over torqued. If it is it can snap the end of the camshaft

off, now you have problems.

Torque down the three injection pump bolts where they are

at.

Double check that the flywheel is still at TDC.

At this point you have the cam locked down, a small

screwdriver wedged in the bell housing holding the flywheel at

TDC, the injection pump lock pin installed in the pump and all

the bolts on the pulleys tightened. The pulley bolts you want

taight at this point are the 3 bolts in the pump, the cam bolt

(33 ft-lbs) and the tensioner nut.

Remove the cam lock bar, injection pump lock pin, screw

driver in the bell housing. REMOVE ALL THE PAPER TOWELS IN

THE INLETS, INCLUDING THEAIR BOX, TURBO INLET, EGR INLET, AND

ANYTHING ELSE THAT WAS PLUGGED.

NOTE: INSTALL THE LONG ENGINE MOUNT BOLT IN THE CENTER

ENGINE MOUNT HOLE TO PREVENT THE NEW TIMING BELT FROM RUBBING

ON THE ENGINE MOUNT IN THE NEXT FEW STEPS.

Using the 3036 holding bar rotate the camshaft counter

clockwise ONLY!! or else you screw up the tension that is set

on the tensioner!! Turn the camshaft/engine one complete

rotation until the the #1 cylinder is back to the "Lobes up"

position (FYI you should feel really good compression when

doing this however compression goes away valves incorrectly

timed do not! If you feel like the engine is hitting a valve

turn it back and recheck all your settings and bolts to make

sure you torqued everything. In the unlikely event that you

got the timing incorrect you cannot damage anything provided

you rotate the engine by hand. If at anytime you change a

timing setting at the cam recheck the rotational clearance

using the 3036 tool and turning the cam one rotation).

Install the front and rear bolt in the vacume pump so

that the oil feed does not shoot oil all over the engine bay.

Be carefull to make sure the o-ring is not pinched in when

tightening it down.

Once you complete a camshaft revolution check that you can

see the TDC mark in your bellhousing window, if you do your

ready to bump the motor.

With somebody in the car you are going to bump the engine

using the starter. The reason is this will get the new timing

belt properly centered on the pulleys and allow the tensioner

to take up any slack in the timing belt. Try not to let the

engine start and bump the engine as many times as required

(3-4 times) until the belt stops moving and is centered on the

"CAMSHAFT" pulley. The injection pump will be somewhat off

center that's totally normal you just want to make sure that

the belt is not riding off the injection pump pulley, if it is

you need to have the bracket either replaced or reshimmed.

Now that you have bumped the motor clear every intake port

once more and start the motor, it should start immediately and

run normally, if not recheck all timing marks you missed

something. When the engine starts shut it off to prevent oil

from going everywhere.

When your closing every thing up a few things to remember:

-Timing belt covers, install the lower cover first, then

the top cover then the engine mount.

-When installing the pendulum mount install the steel

alignment bracket first then install the big mounting bolts.

-Use blue locktite on the 4 harmonic damper bolts.

VAG-COM timing procedure

Start the engine and let it run. Hook up the Vag-Com and

start the software and enter data block 000. Enter "Basic

Settings mode". Read data block 2 and data block 9. If block 9

(fuel temp) is reading 110 then block two should be reading

70. I doubt it is since the timing is only set to be in the

ignition window so shut the engine down. Loosen the three

bolts (DO NOT REMOVE THEM!) on the injection pump. Using your

trusty large crescent wrench gently and very very slowely

rotate the pump counterclockwise to make the number in block 2

increase or clockwise to make it decrease. Increasing the

value of the number in block two will effectively "Advance

your timing".

You of course will have to guess at how much you moved the

pump, retighten the 3 bolts get in start the engine and see

where its at. If the number is not where you want it repeat

the procedure until the setting is where you want on the graph

in the bentley manual (sometimes I am glad one of my cars is

an A3....)

FYI, advancing the timing will reduce smoke output,

increase fuel economy, and make the engine more rev happy. It

will not matter if you are running the .184, .205 or .216

injectors becuase the #3 injector tells the ECU when injection

occurs so the ECU will have all that taken care of.

Break time....my hands hurt

Drivbiwire